The train axle is of good quality. Owing to advanced inspection equipment, we can carry out many tests.

The axle conforms to every recognized international quality standard listed as below. The product can also be made on customer's requirements.

The axle supports adopting many kinds of steel as raw material, such as, LZ50, JZ45, AAR Grade F, EA1N, EA1T, EA4T, IRS 16/95, and SFA60A.

We accept axle orders of small quantity or of demanding complex designs on customized requirements.

In addition to the competitive price and good sales service, we also supply quality assurance and timely technical service. Besides, our delivery lead time is short.

The axle production contains the following processes.

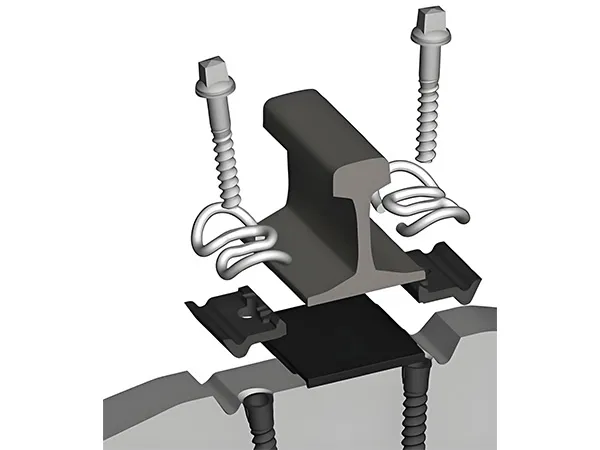

Need reliable railway fastening solutions? Contact us today for more information!

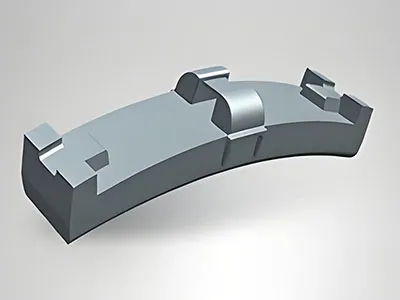

SUYU can offer diversified train wheels like the casting wheel and forging wheel.

SUYU can provide a complete set of rail fastening system of SKL14, SKL12, elastic rail clip system, and Nabal clip system.

SUYU is a specialized rail fastening manufacturer based in China.